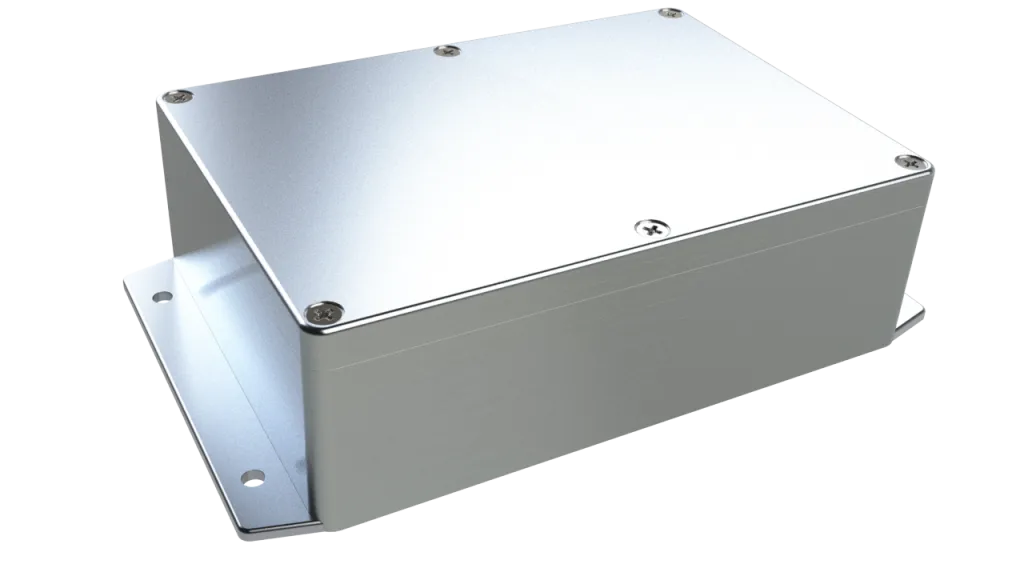

What are Diecast Aluminum NEMA Enclosures?

Diecast aluminum NEMA enclosures are protective housings crafted from diecast aluminum, designed to safeguard electrical components and equipment from various environmental hazards. These enclosures are essential in numerous industries, providing a robust barrier against dust, water, and other potentially damaging elements. The diecasting process involves injecting molten aluminum under high pressure into a mold, resulting in a strong, precise, and durable enclosure. The NEMA (National Electrical Manufacturers Association) rating system further defines the level of protection these enclosures provide, making them suitable for a wide range of applications. Their construction ensures longevity and reliability, critical for protecting sensitive electronic devices and maintaining operational integrity in demanding environments. Selecting the correct enclosure is paramount for ensuring the equipment’s optimal performance and extending its lifespan, making them a vital component in industrial and commercial settings.

Definition and Overview of NEMA Ratings

NEMA ratings are standardized classifications that specify the environmental protection provided by electrical enclosures. They are crucial for matching the enclosure to the specific operational environment. These ratings are not a performance standard but rather a guide for selecting an enclosure capable of meeting a particular set of environmental conditions. Understanding these ratings is essential for ensuring that the equipment housed within the enclosure is adequately protected from external elements. They cover a broad range of potential hazards, from basic protection against solid objects to resistance against water, corrosion, and even hazardous locations. This standardized system allows engineers, technicians, and end-users to make informed decisions when selecting enclosures, ensuring that equipment is both safe and operational. The NEMA rating acts as a clear indicator of the enclosure’s suitability for a given application.

NEMA Ratings Explained

NEMA ratings consist of a number that indicates the level of protection offered by an enclosure. Common ratings include NEMA 1 (indoor use, protects against falling dirt), NEMA 3R (outdoor use, protects against rain, sleet, and snow), and NEMA 4 (indoor/outdoor, protects against water, dust, and hose-directed water). More specialized ratings, such as NEMA 6 and 6P, provide increased protection against water ingress, including submersion. Choosing the appropriate NEMA rating is essential to ensure the safety and longevity of the enclosed equipment. This choice depends on the specific environmental conditions the equipment will face. Higher ratings typically offer greater protection but may also come with increased costs. Careful consideration of the environment helps to prevent premature equipment failure, downtime, and safety hazards. The selection process often involves a thorough assessment of potential risks and the requirements of local regulations.

Benefits of Diecast Aluminum

Diecast aluminum offers several advantages, making it an ideal material for NEMA enclosures. Its strength-to-weight ratio is superior, providing robust protection without adding excessive weight. This is particularly important in applications where ease of installation and handling are crucial. Aluminum’s natural resistance to corrosion is a key benefit, ensuring a long service life even in harsh environments. The material’s excellent thermal conductivity also helps to dissipate heat, which is essential for electronic components that generate significant heat. Moreover, aluminum can be easily shaped into complex designs during the diecasting process, allowing for customized enclosures that meet specific requirements. This flexibility, combined with its recyclability, positions diecast aluminum as a sustainable and cost-effective choice for manufacturing electrical enclosures. The combination of these properties ensures reliability and durability across a wide range of industrial applications.

Durability and Strength

The durability and strength of diecast aluminum are pivotal for protecting sensitive electronic components. The diecasting process results in a dense, solid structure capable of withstanding significant mechanical stress and impacts. This robust construction safeguards the enclosed equipment from physical damage caused by external forces, such as accidental bumps, falling objects, or harsh handling. The material’s high tensile strength ensures that the enclosure remains intact under challenging conditions. Diecast aluminum enclosures are therefore well-suited for applications where the equipment is exposed to potential hazards, from manufacturing floors to outdoor installations. This strength provides a reliable barrier, extending the lifespan of the equipment and reducing the likelihood of costly repairs or replacements. They provide reliable protection, reducing downtime and maintenance expenses.

Corrosion Resistance

Aluminum’s inherent corrosion resistance is another significant advantage. Unlike steel, aluminum forms a natural oxide layer that protects the underlying metal from further degradation when exposed to air and moisture. This property is crucial in environments where enclosures are exposed to corrosive elements such as salt spray, chemicals, or high humidity. The corrosion resistance of diecast aluminum ensures that the enclosure maintains its structural integrity and protective capabilities over time. This reduces the risk of equipment failure and extends the lifespan of the enclosure itself. Proper surface treatments, like powder coating, can further enhance this protection, making the enclosures even more resistant to harsh environmental conditions. By selecting diecast aluminum enclosures, users can significantly reduce maintenance requirements and extend the operational lifespan of their electrical equipment.

Thermal Management

Diecast aluminum exhibits excellent thermal conductivity, a critical characteristic for managing heat generated by electrical components. This property allows the enclosure to effectively dissipate heat, preventing overheating and ensuring optimal performance of the equipment inside. Overheating can significantly reduce the lifespan and efficiency of electronic devices. Aluminum’s ability to conduct heat away from these components helps maintain optimal operating temperatures. The design of the enclosure, including features like cooling fins, can further enhance thermal management. This efficient heat dissipation is particularly valuable in applications where equipment operates continuously or generates significant heat. It helps maintain equipment reliability, reduces the risk of premature failure, and minimizes maintenance costs. Diecast aluminum enclosures are crucial for maintaining the long-term performance and reliability of sensitive electronic components by effectively managing heat buildup.

Choosing the Right Diecast Aluminum NEMA Enclosure

Selecting the right diecast aluminum NEMA enclosure involves a careful assessment of several factors. The primary consideration is the environment in which the enclosure will be used. This includes factors such as temperature range, humidity levels, the presence of corrosive substances, and potential exposure to water or dust. The NEMA rating required to provide adequate protection will depend on these environmental conditions. Next, the size and dimensions of the enclosure must accommodate the equipment being housed, while also allowing for proper ventilation and ease of access for maintenance. Furthermore, it is important to consider the specific application of the enclosure, as this can influence the required features, such as mounting options, cable entry points, and the need for additional accessories. Careful consideration of these factors is essential for selecting an enclosure that provides optimal protection, performance, and long-term reliability.

Factors to Consider

Several specific factors should be considered when selecting a diecast aluminum NEMA enclosure. The NEMA rating is paramount, as it dictates the level of environmental protection provided. The size and internal dimensions of the enclosure must be adequate for the equipment, with enough space for proper wiring and airflow. The enclosure’s mounting options, such as wall-mount or floor-mount, need to be compatible with the installation environment. Cable entry points should be strategically placed to prevent water and dust ingress while allowing for easy access to cables. Additional features like ventilation, grounding provisions, and the availability of accessories such as terminal blocks and mounting hardware are essential. The overall design of the enclosure should facilitate easy access for maintenance and inspection. All these factors contribute to the proper function and longevity of the protected equipment, making each selection crucial for system reliability.

Size and Dimensions

The size and dimensions of the NEMA enclosure must be carefully chosen to accommodate the electrical components and equipment being protected. The internal dimensions must be sufficient to house all the necessary devices, including circuit breakers, terminals, control units, and any associated wiring. It is crucial to consider future expansion or additions to the equipment. Too small of an enclosure will make maintenance difficult and could impede airflow, leading to overheating. The external dimensions should fit the mounting space available, whether on a wall, a machine, or a custom-built structure. Standard sizes are available, but custom enclosures can be manufactured to meet specific size requirements. Correctly sizing the enclosure ensures both adequate space for the equipment and efficient operation, while also facilitating maintenance and enhancing the overall safety and accessibility of the system.

NEMA Rating Requirements

Selecting the appropriate NEMA rating is paramount for the reliable operation of diecast aluminum enclosures. The rating should correspond to the environmental conditions the enclosure will face. For example, NEMA 1 enclosures are suitable for indoor use where protection against falling dirt is needed. NEMA 3R enclosures are designed for outdoor use and provide protection against rain, sleet, and snow. For applications requiring protection from hose-directed water or dust, NEMA 4 enclosures are appropriate. More stringent conditions, such as exposure to corrosive substances or submersion, necessitate higher ratings like NEMA 6 or 6P. A detailed understanding of the environmental factors present at the installation site is necessary to make the correct selection. This ensures the enclosed equipment is adequately protected from potential hazards, thereby extending its lifespan and preventing costly downtime or equipment failure. Failing to choose the right NEMA rating can expose sensitive components to damage.

Environmental Conditions

The environmental conditions to which the enclosure will be exposed are the primary determinant for selecting the correct diecast aluminum NEMA enclosure. Factors such as temperature range, humidity levels, the presence of dust, and the risk of water exposure must all be carefully assessed. High temperatures may necessitate enclosures with superior thermal management capabilities to prevent overheating. High humidity or exposure to water requires enclosures with higher NEMA ratings to protect against moisture ingress. The presence of corrosive substances such as salt spray or chemicals also influences the selection, as these can compromise the enclosure’s material integrity. Understanding these conditions allows the selection of an enclosure that provides the necessary level of protection, thereby ensuring the longevity and reliability of the equipment it houses. Proper selection of the enclosure in respect to environmental conditions is crucial for both safety and the operational effectiveness of the protected devices.

Applications of Diecast Aluminum NEMA Enclosures

Diecast aluminum NEMA enclosures are used across a wide spectrum of industries and applications, providing essential protection for electrical and electronic components. Their versatility, durability, and resistance to environmental factors make them ideal for a variety of settings. From industrial automation to telecommunications and outdoor electrical equipment, these enclosures play a critical role in ensuring the reliable operation of sensitive devices. Their rugged construction and ability to withstand harsh conditions contribute significantly to the long-term performance and safety of the equipment they house. As technology advances and new applications emerge, the demand for robust and reliable enclosure solutions continues to grow, further solidifying the importance of diecast aluminum NEMA enclosures in modern industry.

Industrial Automation

In industrial automation, diecast aluminum NEMA enclosures are widely used to protect control systems, motor starters, and other critical components from dust, moisture, and physical damage. They are often installed in harsh environments such as manufacturing plants, where machinery generates heat and debris. The enclosures provide a secure and reliable housing for electrical equipment, ensuring uninterrupted operation of automated processes. Their resistance to corrosion and their ability to withstand mechanical stress make them ideal for environments where equipment must function reliably under demanding conditions. They are essential components in ensuring the efficiency and safety of modern industrial processes, contributing to increased productivity and reduced downtime. These enclosures facilitate the smooth operation of complex machinery and systems, providing a barrier to prevent malfunctions.

Outdoor Electrical Equipment

Outdoor electrical equipment, such as traffic control systems, security cameras, and outdoor lighting, heavily relies on diecast aluminum NEMA enclosures. These enclosures are designed to withstand the elements, including rain, snow, and direct sunlight. The corrosion resistance of aluminum is particularly beneficial in outdoor settings where the equipment is exposed to moisture and fluctuating temperatures. The enclosures provide a secure and weatherproof housing that protects sensitive electronic components from environmental damage, ensuring reliable operation. They are a critical component in maintaining public safety and infrastructure, providing the necessary protection for devices that operate around the clock, irrespective of weather conditions. The robust construction and protective features ensure these systems remain functional, even in challenging environments.

Telecommunications

The telecommunications industry employs diecast aluminum NEMA enclosures to protect various equipment, including base stations, routers, and other network devices. These enclosures are essential for safeguarding the sensitive electronics that facilitate communication networks from environmental factors. Their durability and resistance to interference make them ideal for housing equipment deployed in both indoor and outdoor locations. The enclosures often include features for managing heat dissipation, which is critical for maintaining the performance and longevity of the equipment. By protecting the components from environmental factors, diecast aluminum NEMA enclosures play a critical role in maintaining the reliability and efficiency of telecommunications networks, ensuring that communication services are consistently available.

Installation and Maintenance Tips

Proper installation and maintenance practices are crucial for maximizing the lifespan and performance of diecast aluminum NEMA enclosures. Correct installation ensures that the enclosure functions as intended, providing the necessary level of protection. Regular maintenance, including inspections and cleaning, helps to identify and address potential issues before they cause problems. Adhering to these practices ensures the reliability of the protected equipment and reduces the risk of premature failure or downtime. Regular attention can prevent corrosion, water ingress, and other environmental hazards that could compromise the functionality of the enclosure and its contents. Proper installation and maintenance practices contribute significantly to the overall effectiveness and long-term reliability of the system.

Proper Installation Techniques

Proper installation of a diecast aluminum NEMA enclosure begins with ensuring that the mounting surface is level and stable. The enclosure should be securely fastened using the appropriate hardware. Cable entry points must be properly sealed to prevent water and dust ingress. Wiring should be neatly organized within the enclosure, and all connections must be securely tightened. Ensure that the enclosure’s grounding provisions are correctly connected to provide a safe electrical system. Follow the manufacturer’s instructions carefully to ensure the enclosure functions correctly and provides the intended level of protection. Proper installation, including attention to detail in sealing and wiring, is critical to prevent environmental hazards from affecting the enclosed equipment and helps ensure safety and optimal performance.

Regular Inspection and Maintenance

Regular inspection and maintenance are vital for ensuring the long-term performance and reliability of diecast aluminum NEMA enclosures. Routine inspections should be performed to check for any signs of damage, corrosion, or wear and tear. The enclosure should be cleaned regularly to remove dust, dirt, and debris that could compromise its protective capabilities. Check the seals and gaskets to ensure they are in good condition and properly sealing the enclosure. Inspect the cable entry points and ensure they remain sealed. Any issues identified during inspection should be addressed promptly. Following these maintenance steps helps to extend the lifespan of the enclosure and the equipment it protects. Regularly scheduled maintenance reduces the risk of equipment failure and prevents costly repairs or replacements. Proper maintenance is an investment in the reliability and longevity of the enclosed equipment.

Troubleshooting Common Issues

Several common issues can affect the performance of diecast aluminum NEMA enclosures. Water ingress is a frequent problem, which can be caused by damaged seals, improper installation, or physical damage to the enclosure. Corrosion can occur due to exposure to corrosive elements, such as salt spray or chemicals. Overheating can arise if the enclosure is inadequately ventilated or if the equipment generates excessive heat. Loose wiring and connections can lead to electrical malfunctions and safety hazards. Troubleshooting involves identifying the root cause of the problem. Regularly inspecting the enclosure for signs of wear, damage, or malfunction can help identify issues. Addressing these problems through repairs or replacements can prevent further damage and ensure the ongoing performance of the protected equipment. Corrective actions, along with maintenance, are essential for maintaining the longevity and functionality of the enclosures.