What is Diecast Aluminum Chrome Plating?

Chrome plating diecast aluminum is a surface finishing process that involves applying a thin layer of chromium to a diecast aluminum part. This process enhances the appearance, durability, and corrosion resistance of the aluminum. It’s a popular technique used across various industries, including automotive, appliance manufacturing, and decorative arts. The process requires several steps, each crucial for achieving a high-quality, long-lasting finish. Understanding the fundamentals of both diecast aluminum and chrome plating is essential to successfully applying this process.

Understanding Diecast Aluminum

Diecast aluminum is produced by injecting molten aluminum alloy under high pressure into a mold. This process creates intricate and complex shapes with tight tolerances. The resulting parts are lightweight, strong, and cost-effective for mass production. The alloy composition typically includes aluminum along with other elements like silicon, copper, and magnesium, which enhance its mechanical properties and improve its castability.

Properties of Diecast Aluminum

Diecast aluminum offers several advantages, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. These properties make it suitable for a wide range of applications. However, the surface of diecast aluminum can be porous, which requires careful preparation before chrome plating to ensure proper adhesion and a smooth, even finish. The alloy’s composition significantly impacts the plating process, demanding specific pre-treatment steps to ensure optimal results.

Why Chrome Plate Diecast Aluminum?

Chrome plating enhances the value of diecast aluminum parts in several ways. The primary reasons for choosing chrome plating are improved aesthetics, increased durability, and enhanced corrosion protection. It gives a bright, shiny finish that significantly improves the visual appeal of the part. Additionally, the chromium layer acts as a barrier against environmental factors, reducing wear and tear and extending the lifespan of the aluminum component, particularly in applications exposed to the elements or frequent use.

Benefits of Chrome Plating

The benefits of chrome plating are numerous. Chrome plating provides a highly reflective and attractive surface, which is essential for decorative applications. It also increases the surface hardness, making the part more resistant to scratches, abrasion, and other forms of mechanical damage. Furthermore, chrome plating enhances the corrosion resistance of the diecast aluminum, protecting it from rust and other forms of degradation, leading to a longer service life.

Safety Precautions

Chrome plating involves the use of hazardous chemicals and processes. Safety should always be the top priority. Proper ventilation is essential to prevent the inhalation of harmful fumes, and personal protective equipment (PPE), including gloves, eye protection, and appropriate clothing, must be worn at all times. The plating process generates heat, so care should be taken to avoid burns. Dispose of chemical waste responsibly, following local regulations. Before starting any chrome plating project, always consult the safety data sheets (SDS) for all chemicals involved.

Necessary Equipment and Materials

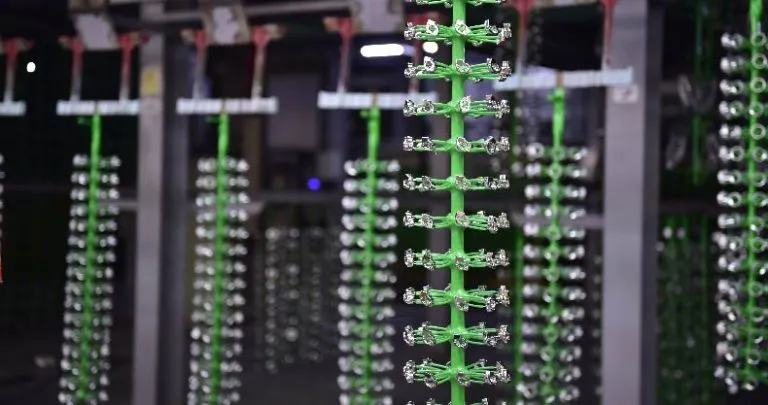

To chrome plate diecast aluminum, you will need specific equipment and materials. This includes a plating tank, power supply, anodes (usually made of chromium, copper or nickel), various plating solutions (copper, nickel, and chrome), and cleaning chemicals. You will also require PPE, polishing tools, and a means of suspending the parts in the plating bath. Proper filtration systems are essential to maintain the purity of the plating solutions, which ensures quality results. The availability of these resources is crucial before starting.

Preparing the Diecast Aluminum Surface

Proper surface preparation is the most important step for successful chrome plating. The diecast aluminum surface must be thoroughly cleaned and free of any contaminants, such as oils, grease, and oxides. This ensures that the plating adheres properly and provides a smooth, even finish. A well-prepared surface creates the foundation for a long-lasting and aesthetically pleasing chrome coating. Any imperfections or contaminants will show through the plating, so meticulous attention to detail is critical at this stage.

Cleaning and Degreasing

Cleaning and degreasing the aluminum is the first step. Use a degreasing solution, typically an alkaline cleaner, to remove any oils, grease, or other contaminants from the surface. This can involve a hot soak in the cleaning solution, followed by rinsing with clean water. Ultrasonic cleaning can enhance the effectiveness of degreasing, especially for parts with intricate geometries. Ensure all traces of the cleaning solution are removed by thoroughly rinsing with deionized water.

Sanding and Polishing

After cleaning, the surface may need sanding and polishing. Use abrasive pads or polishing wheels to remove any imperfections, such as scratches or surface roughness. The goal is to achieve a smooth, reflective surface before plating. The polishing process enhances the final appearance of the chrome finish. The degree of polishing required depends on the desired level of shine. Follow the sanding with finer and finer grits to achieve the desired finish.

The Chrome Plating Process

The chrome plating process involves several distinct steps, including pre-treatment, copper plating, nickel plating, and finally, chrome plating. Each step serves a specific purpose and contributes to the overall quality and durability of the finish. It’s crucial to adhere to the recommended procedures and parameters for each step to achieve optimal results. This multi-step process provides corrosion resistance, improves aesthetics, and ensures a long-lasting finish.

Step 1 Pre-treatment

Pre-treatment involves a series of steps to prepare the aluminum surface for plating. This might include etching the surface to improve adhesion, followed by a zincating process. Zincating involves creating a thin layer of zinc on the aluminum, which acts as a base for the subsequent copper and nickel plating layers. Thorough pre-treatment is critical for preventing issues such as blistering and poor adhesion.

Step 2 Copper Plating

Copper plating is often the first layer applied over the pre-treated aluminum. Copper plating provides a good base for the subsequent nickel plating and helps to level the surface, filling in any minor imperfections. The copper layer also improves adhesion. This layer is usually electrodeposited from a copper sulfate or cyanide solution. The thickness of the copper layer is controlled to ensure adequate coverage and protection.

Step 3 Nickel Plating

Nickel plating is applied over the copper layer. Nickel plating enhances corrosion resistance and provides a smoother surface for the final chrome layer. Nickel plating can also improve the brightness and reflectivity of the finish. The nickel layer also acts as a barrier, preventing the underlying copper from migrating to the surface. Several types of nickel plating solutions can be used, each with unique properties.

Step 4 Chrome Plating

The final step is chrome plating. This involves electrodepositing a thin layer of chromium onto the nickel surface. This gives the part its characteristic shiny appearance and provides additional corrosion resistance. Chrome plating is done in a chromic acid solution, and the thickness of the chrome layer is carefully controlled. The plating time and current density are critical parameters that affect the quality and appearance of the final finish.

Post-Plating Treatment

After chrome plating, the parts undergo post-plating treatment to ensure a high-quality finish. This includes rinsing, drying, and sometimes additional treatments to enhance the surface properties. These steps are crucial to remove any remaining plating solutions and to ensure a durable and visually appealing finish. The right post-treatment steps are vital for the long-term performance of the chrome-plated parts.

Rinsing and Drying

Rinsing is essential to remove any remaining plating solutions or chemicals from the surface of the part. This is usually done with clean, deionized water. Proper rinsing prevents the formation of spots or stains on the finished surface. After rinsing, the parts are dried. Drying can be done using air drying or, more commonly, with a heated oven to eliminate any water spots. This prevents any rust or corrosion.

Quality Control and Inspection

Quality control and inspection are crucial steps to ensure the chrome-plated parts meet the required standards. This includes visual inspections for defects such as uneven plating, blisters, and discoloration. The thickness of the chrome layer is often measured using specialized instruments. Salt spray testing can be used to assess the corrosion resistance of the plated parts. Regular inspections throughout the process are important for catching any issues early on and maintaining the required quality.

Common Problems and Troubleshooting

Even when following all the steps carefully, problems can arise during chrome plating. Understanding these potential issues and how to troubleshoot them is crucial for achieving successful results. Common problems include poor adhesion, uneven plating, and corrosion. The ability to diagnose and correct these issues is key to the overall success of the process. Recognizing these problems early saves time and resources.

Poor Adhesion

Poor adhesion is a common problem, where the plating does not properly stick to the aluminum surface. This can be caused by inadequate surface preparation, such as not removing all the contaminants. Improper pre-treatment steps can also lead to poor adhesion. Make sure the surface is thoroughly cleaned, pre-treated correctly, and that the correct plating parameters are used. If adhesion is poor, it can lead to blistering, peeling, and premature failure.

Uneven Plating

Uneven plating can result in a non-uniform appearance, with areas of thin or thick chrome. This can be caused by uneven current distribution in the plating tank. Ensure proper racking of the parts and that the anodes are positioned correctly. The plating solution may also have problems. Proper agitation and temperature control are essential to achieve an even plating distribution. Poor cleaning can also cause uneven plating.

Alternatives to Chrome Plating

While chrome plating is popular, there are alternatives to consider. These alternatives offer different properties and benefits. The best choice depends on the specific application and desired characteristics of the finish. Alternatives include powder coating, anodizing, and physical vapor deposition (PVD) coatings. Each has its own advantages and disadvantages in terms of cost, durability, and appearance.

Conclusion

Chrome plating diecast aluminum is a complex but rewarding process that enhances both the appearance and durability of aluminum parts. From surface preparation to the final plating, each step plays a crucial role in the final outcome. By following the correct procedures, understanding the potential problems, and implementing effective quality control measures, you can achieve a high-quality, long-lasting chrome finish. This guide provides a comprehensive overview, but always consult the safety and technical data sheets for precise instructions and precautions before starting.